Steam power plant boiler water screen in service vortex flaw detection

Power plant 300MW boiler water screen tube in service vortex flaw detection

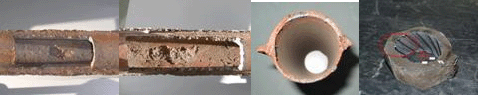

Steam power plant boiler wall screen is running under high temperature high pressure,due to inner wall corrosion pit、hydrogen embrittlement crack,the tube cracked from time to time。it is necessary to search and fix recessive flaw in maintenance period so as to put the end to unexpected incident

Adopting steel tube corrosion scanning machine ,attached on steel tube external wall as saddle probe,no need to clean oxide layer on the surface ,high precision,fast speed

The boiler water screen with being detected corrosion、wall thickness reduction、hydrogen embrittlement

Flow detection uses offline or online to detect surface of metal bar,tube,seamless tube,welded pipe and belt materials,near surface 、inner surface and inner flaw usually adopt outside wear probe,the detected material cross probe and detect;high frequency welded tube online vortex flaw detection can also adopt saddle magnetic saturation、saddle probe to detect quality of welding line,including lack of fusion、slag inclusion、sand hole、air hole、and other flaws.

When material area is big or shape is complex with high requirement,then it needs to adopt spot probe,manual or equipped with automatic scanning equipment to realize one by one scanning detection。

Different detecting ways need to adopt different auxiliary equipment,or suitable for situation,fully take advantage of current equipment of production scene ,design special auxiliary instrument to realize。for liquidity scene,usually adopt simple convenient auxiliary instrument to realize,manual way is available。

+86 13616209379

+86 13616209379